The digital solution that takes your manufacturing to its peak in terms of cost efficiency, productivity, and quality.

Your Production, Your Control

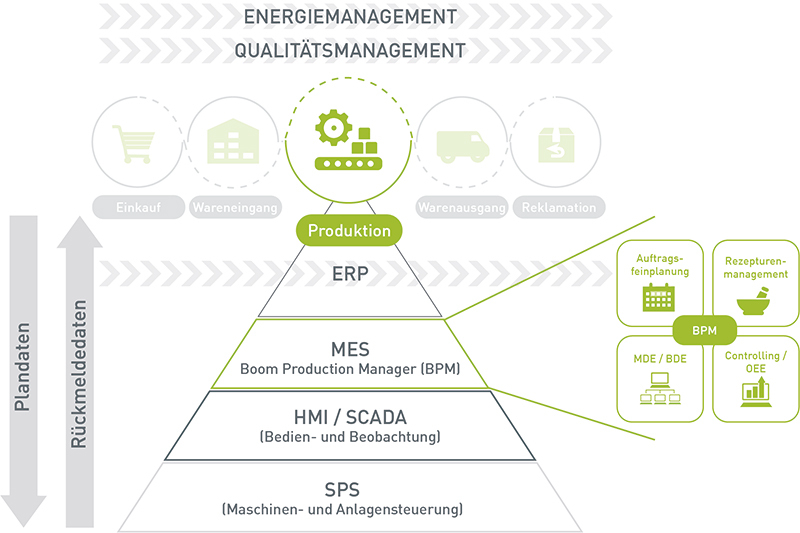

The Boom Production Manager (BPM) is akin to a Manufacturing Execution System (MES) and is designed to enhance your manufacturing process. It accomplishes this by seamlessly overseeing, tracking, documenting, and managing the entire production cycle, elevating your manufacturing operations to a new level.

With BPM, we guarantee that you retain command over your production processes as it possesses the flexibility to adapt to your specific requirements.

Our technology empowers you to monitor, oversee, and optimize your production workflows in real-time. You have authority over crucial aspects such as quality, efficiency, and costs. This capability allows you to swiftly respond to changes and ensure that your manufacturing consistently operates at peak efficiency.

Utilize the Boom Production Manager to unveil untapped potential and enhance the efficiency of your manufacturing operations in real-time.

Up-to-date production overview at any time

Efficient Planning, Control, and Evaluation of Production Orders

Calculation of optimal setup data based on real data

Through reduced scrap rates and equipment downtime

From raw materials and resources

Early detection of quality defects

Information about machine performance and process data

Monitoring and optimization of energy consumption

The Boom Production Manager serves as a crucial functional interface between ERP and process control systems as an MES (Manufacturing Execution System). The BPM is highly adaptable and flexible, capable of supporting both complex and simple production processes and systems. Furthermore, it provides all functions within the company with the necessary information and support.

The C-level receives comprehensive reports and analyses that serve as the basis for strategic decisions. Automatic notifications ensure that the required information is available in a timely manner.

The Production Management benefits from powerful planning tools and analyses necessary for efficient production control. Deviations from plans are visible at any time and can be addressed promptly if needed.

In quality management, all documented data is consolidated, making it possible to trace changes in recipes, equipment specifications, and more at any given moment, along with their impact on product quality. All steps and process parameters are extensively and securely documented.

For production personnel , pending orders are prepared by the BPM with all relevant information. Equipment specifications and recipes can be automatically transmitted to the equipment as needed. Monitoring of process parameters and notifications of limit violations support production staff in optimizing equipment operation.

In the ever-evolving manufacturing and production landscape, the concept of quality forecasting has proven to be pioneering. This innovative approach leverages state-of-the-art technologies and data analysis to generate forecasts and ensure the highest quality standards in manufacturing processes.

If you too wish to take this step, please feel free to contact our experts for further details.

The modular structure of our Boom Production Manager consists of a base that includes the functionalities of ODA and MDA, along with various expansion modules specifically tailored for production management. The choice of scope is entirely in your hands.

In an initial consultation, you and we will already gain a clear understanding of which functionalities and modules are critical for your requirements. In a subsequent customer workshop, we deepen this understanding through close collaboration. Here, we define the processes that our solution should support and clarify your specific requirements in detail.

What makes our solution particularly attractive is our unique licensing structure. Instead of paying per user, licensing is based on the number of assets you manage in the system. This flexible billing method allows you to cost-effectively and scale your use of our solution, regardless of your company’s size.

Our satisfied customers are the best testament to the quality of our solution.

By utilizing both the Boom Production Manager for controlling and planning production processes and the Boom Maintenance Manager for optimal maintenance of facilities, companies achieve increased overall efficiency in their operations.

Are you interested in consultation? Feel free to get in touch with us.

by reducing downtimes and unplanned machine breakdowns

by being able to respond to predictable maintenance needs

by collecting and sharing machine and process data

by implementing preventive maintenance measures

Contact us today to learn more about how our BPM can accelerate your business.

Together, we shape the future of your manufacturing.

We are pleased that you are interested in our service portfolio. If you need more information, have any questions, or are considering collaboration, please feel free to contact us.

Receive our latest newsletters directly to your inbox!